|

Rui'an Changhong Printing Machinery Factory

|

flexo printer

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

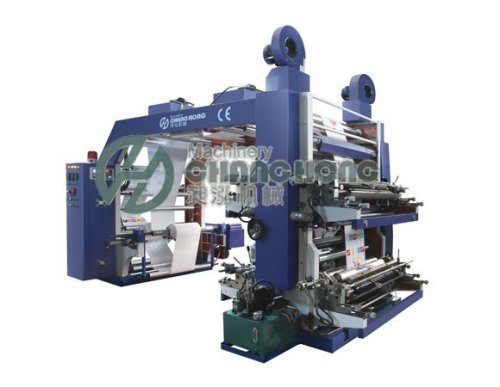

a kind of machine which can print on PE ,pp ,paper .non woven sack ,clothes ,pp nonwven sack for pp woven sack and so .

High Speed 4 Color Flexographic Film Printing Machine(CH884)

The detailed normal confirguration is as below:

The main features:

1. Take it easy, accurate color, long life

2. The use of motors, variable frequency speed control, saving electricity, running small fluctuations

3. Off printing roll automatic stop the ink-running motor, and up-printing roll automatic start running the ink

4. The use of special diagonal-tooth gear, print size is accurate,

5. There are two sets of heating devices, including central heating and constant temperature control system for packet control

6. Low-roller special steel processing, and special process, and plating thickness of 0.1mm protective layer of hard chromium

7. Alloy roll with hard oxidation, treating by dynamic balance, static balanced

8. With a cold wind bellows, and can effectively prevent produce with ink adhesion after printing

9. the Print produce are clear and good arrangement quality

10. Bearing: NSK, Japan brand , Germany ASNU aluminum alloy roll,

Printing width Item | 600mm | 800mm | 1000mm | 1200mm | 1400mm | 1600mm | 1800mm | 2000mm |

Printing color | PC:4+0;3+1;2+2 | |||||||

Printing length | 7.5"-40"/7.5"-50"/7.5"-60"/7.5"-70"/7.5"-80" | |||||||

Printing plate lifting system | Pneumatic/Hydraulic press control/Menu | |||||||

Mechanical speed | 90m/min | |||||||

Printing speed | 70m/min | |||||||

Anilox cylinder | Metal: 10DK-120DK(Germany) | |||||||

Register precision | Longitude:±0.25mm Transverse:±0.25mm | |||||||

Rewinder/Unwinder DIA | ø 600mm | |||||||

Master motor | 3.0KW | 3.0KW | 3.7KW | 3.7KW | 5.5KW | 5.5KW | 7.5KW | 7.5KW |

Unwinder motor | 1.1 KW | 1.5 KW | 2.2 KW | 3.0 KW | ||||

Rewinder motor | 1.5 KW | 2.2 KW | 3.0 KW | 3.7KW | ||||

Electrical header | 14KW | 16KW | 20KW | 22KW | 24KW | 26KW | 28KW | 30KW |

Blower of header | 1.5KW×2 | 1.1KW×3 | 1.1KW×3 | 1.1KW×3 | 1.5KW×3 | 1.5Kw×3 | 2.2KW×3 | 2.2KW×3 |

Blower of nature wind | 0.75 KW | 0.75 KW | 1.1 KW | 1.1 KW | 1.1 KW | 1.5KW | 1.5KW | 1.5KW |

Inking motor | 750W | 750W | 750W | 750W | 750W | 750W | 750W | 750W |

Master frequency converter | Panasonic/ Toshiba transducer Japan | |||||||

Bearing | Japan(NSK) | |||||||

Unilateral bearing | ASNU (Germany) | |||||||

Weight | 3500Kg | 3750Kg | 4000Kg | 4250 Kg | 4500Kg | 4750Kg | 5000Kg | 5300Kg |

Master power | 20KW | 22KW | 26KW | 28KW | 34KW | 37KW | 45KW | 48KW |

Dimension (L×W×H) | 4.5m × 1.8m × 2.5m | 4.5m × 2.0m × 2.5m | 4.5m × 2.2m × 26m | 4.5m × 2.4m × 2.6m | 4.5m × 2.6m × 2.7m | 4.5m × 2.8m × 2.7m | 4.5m × 3.0m × 2.7m | 4.5m × 3.2m × 2.7m |

The detailed normal confirguration is as below:

1. Major configuration

1. Low speed and full load startup; Stable running by tension control when increasing and decreasing speed, noise is decreased

2. High dots presentation rate under high speed; Clear and vivid stratification of screen printing; Strong stereo effect and accurate registering.

3. Aluminum roller adopts the Japan semi-sealing small bearing; Flinty oxidation, static and dynamic balancing treatments are conducted; Low resistance and small flop.

4. The special made modulus angular gears adopted; Accurate printing size and full printing specifications (5mm is a spec)

5. With the air exhaust, blowing and heating settings; The heating system adopts the central thermostatic control system and group management, also with the cold air forming devices.

6. Printing rolls should keep moving while machine halted

7. Material holder use air shaft

8. Autotension control

9. Unwind with auto deviation correction system (EPC)

10. EDGE position control

11. Reversible printing 4 color press for4+0, 1+3, 2+2.

12.1 sets of printing cylinder, sizes: 15 inches.

1. Low speed and full load startup; Stable running by tension control when increasing and decreasing speed, noise is decreased

2. High dots presentation rate under high speed; Clear and vivid stratification of screen printing; Strong stereo effect and accurate registering.

3. Aluminum roller adopts the Japan semi-sealing small bearing; Flinty oxidation, static and dynamic balancing treatments are conducted; Low resistance and small flop.

4. The special made modulus angular gears adopted; Accurate printing size and full printing specifications (5mm is a spec)

5. With the air exhaust, blowing and heating settings; The heating system adopts the central thermostatic control system and group management, also with the cold air forming devices.

6. Printing rolls should keep moving while machine halted

7. Material holder use air shaft

8. Autotension control

9. Unwind with auto deviation correction system (EPC)

10. EDGE position control

11. Reversible printing 4 color press for4+0, 1+3, 2+2.

12.1 sets of printing cylinder, sizes: 15 inches.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Flexo Printer Machine

Flexo

Flexo Printing

Flexo Inks

Flexo Printing Machine

Label Flexo Printing Machine

More>>

.jpg)